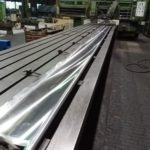

One of our customers sought to optimize the efficiency of their shoe press module through refurbishment. The relative machine data are as follows:

- Shoe width: Approximately 8000 mm

- Type: Single piston hydraulic module

- Net weight: 9100 kg

The scope of the work was a comprehensive refurbishment of the hydraulic module.

Adhering to Techso’s standard protocol, the hydraulic module, inclusive of the piston and shoe, underwent a thorough disassembly, inspection, and precise measurement to identify components necessitating replacement or repair.

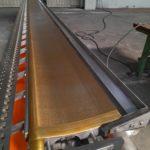

Following the inspection, it was determined that the shoe required grinding and polishing, the piston slot required machining, a complete new piston along with necessary accessories were to be supplied, and the main beam required reconditioning.

Subsequently, the refurbished and new components were meticulously reassembled and returned to the mill alongside a comprehensive job report.

- How it came

- Faults

- Before rectification

- After rectification

- New piston machining

- Skid polishing

- Painting

- End of installation

- Delivery