In a recent project where the Key Objectives were:

-

Reduction of energy consumption

-

Decrease in maintenance costs

-

Vibration reduction

We achieved some significant results.

The primary outcome was a substantial reduction in power consumption, coupled with the elimination of mechanical and maintenance problems associated with gears. Additionally, vibrations experienced a significant decrease.

How we did:

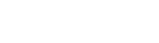

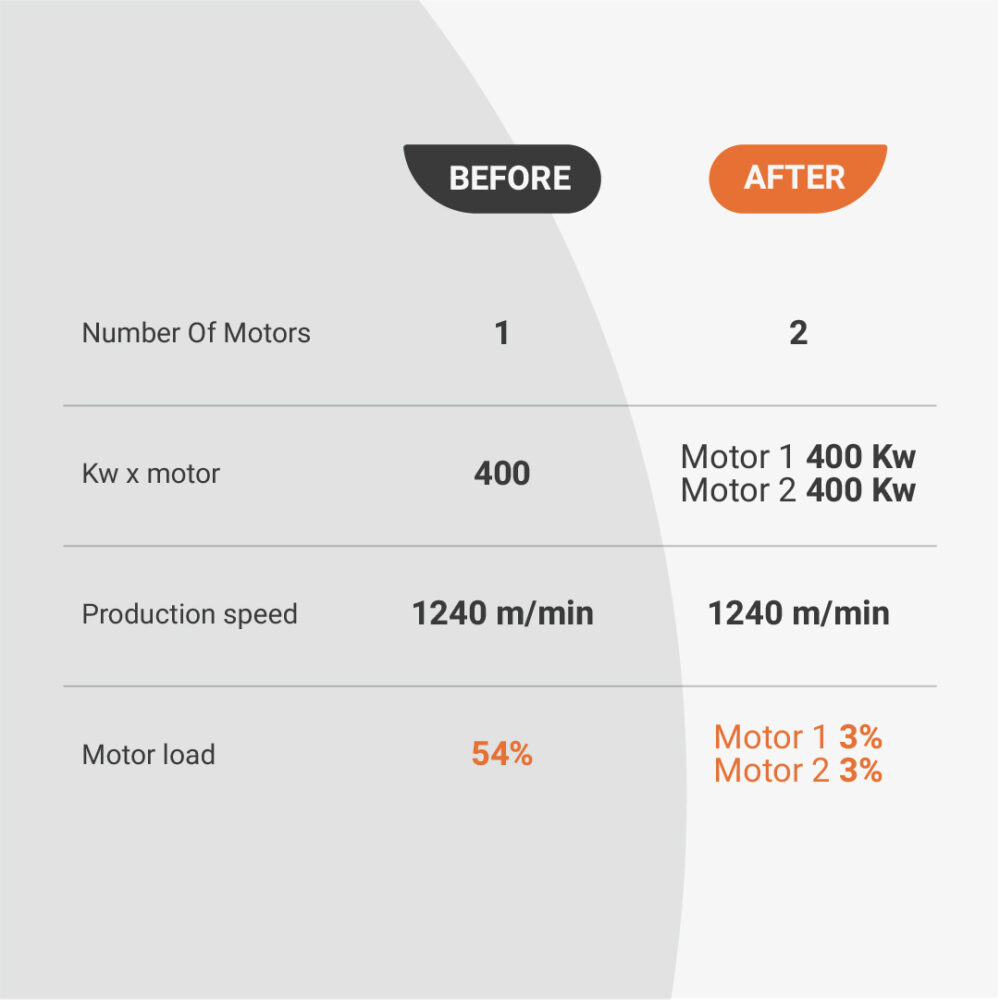

In Pre-Modification scenario the dryer sections were previously driven by closed gears, leading to various issues, primarily associated with high energy consumption and elevated maintenance costs arising from mechanical problems linked to gear wear.

In the new system we revamped the dryer section group by eliminating all intermediate gears and implementing a silent drive system directly powering two dryer cylinders. The existing gear case supporting the dryer cylinders was retained, integrating two new structures to support the new direct gearboxes. The old single-drive motor (400 kW) was replaced with two new motors of 400 kW each (in line with customer standards), with the flexibility to run on a single motor in case of emergency. The installation required 8 working shifts in addition to pre-shutdown preparatory activities.

Contact us for more information.